design factory for processing copper ore

Copper Mining and Processing: Processing Copper Ores

2 之 Copper processing is a complicated process that begins with mining of the ore (less than 1% copper) and ends with sheets of 99.99% pure copper called cathodes,

Innovative process design for copper-cobalt oxide ores in

SYNOPSIS. The mining industry in the Democratic Republic of Congo has seen a significant expansion in copper and cobalt production in recent years. The greater proportion of this

Copper Processing Equipment, Process Flow,

2023年4月26日 Copper ore processing. According to the metallurgy process, the copper ore is divided into three natural types by the ratio of copper oxide and copper sulfide. That is, sulfide ore, containing less than

Copper processing Ores Britannica

Principal forms in which copper ores are found include native copper, porphyry copper, massive deposits, and mixed ores. Native copper is simply the metal found unadulterated

COPPER FLOTATION PLANT Pineer Mining Machinery

2022年3月1日 OPERATIONPROCESS DESIGN. According to the processing order of the useful mineral, the copper ore processing/mining can be divided into precedence

From Ore to Finished Product Copper

4. Beneficiation of Copper Ore. The next step in processing is called beneficiation. This is the first step in concentrating the copper into a more useable form. 5. Smelting and

Copper Ore Processing Methods Metallurgist

2017年4月11日 Copper Ore Processing Methods. The four major steps in the production of marketable copper are mining, concentrating, smelting, and refining. In a few instances, however, leaching takes the place of

Design Factory For Processing Copper Ore HN droled

Mekanism Ore Processing Official Feed The Beast Wiki. Dec 13, 2017 A Review on Novel Techniques for Chalcopyrite Ore Processing. 2.2.2.1.1. Intec Copper Process The intec

design factory for processing copper ore

Copper ore processing. According to the metallurgy process, the copper ore is divided into three natural types by the ratio of copper oxide and copper sulfide. That is, sulfide ore,

Copper-processing technologies: Growing global copper

2023年2月17日 The analysis in this article was enabled by MineSpans, which is a proprietary McKinsey solution that provides mining operators and investors with robust cost curves, commodity supply and demand models, and detailed bottom-up models of individual mines.. For copper, MineSpans offers mine-level data on 390 primary copper mines and

Minerals Special Issue : Recent Advances in Copper Ore

2022年1月28日 Producers, however, are facing challenges due to falling head grades and more complex ore mineralogy. In this Special Issue, recent advances in copper ore processing and extraction are discussed, focusing on: innovations in hydrometallurgical, pyrometallurgical, electrometallurgical, and pre-concentration technologies; improving

Processing of Complex Materials in the Copper

2020年7月6日 A global copper mine-by-mine review undertaken by ICSG found that the global average copper ore grade was as low as 0.45% copper in reported reserves and only 0.65% copper in 2015 copper mine

Optimization of Ore Production in Copper Mine

2020年1月8日 In this feasibility study on optimizing copper ore production, first, we will analyze the copper ore production capacity of the Mujicun copper mine (Hebei province, China) base on the production plans of 3.5 million t/a, 4.5 million t/a, 5.5 million t/a. Then, after the comparison of the three production plans, the op-

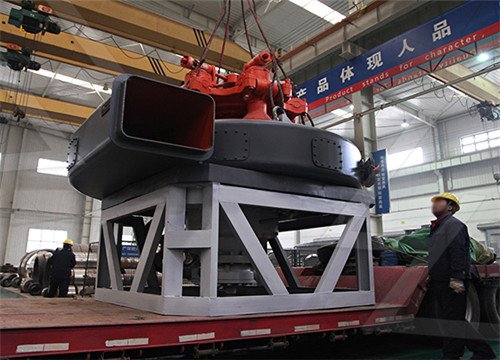

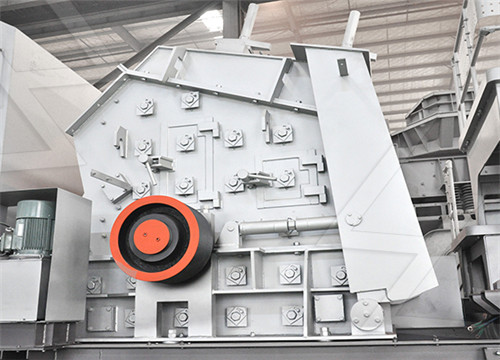

Copper Beneficiation Process, Equipment Mineral

This setup is a complete set rock copper processing plant, including crushing, grinding, grading, sieving, separation, drying and other processes. Below is copper mining equipment: 1. Crushinggrinding: The chute feeder is for feeding raw material to primary jaw crusher more stable and smoothly.

COPPER FLOTATION PLANT Pineer Mining Machinery

2022年3月1日 OPERATIONPROCESS DESIGN. According to the processing order of the useful mineral, the copper ore processing/mining can be divided into precedence flotation, equivalent flotation, mixed flotation, and partial flotation. Normally 30% T/T deposit in advance, the balance 70% T/T before delivery from the factory. Please Leave

Copper Ore Processing Methods Metallurgist

2017年4月11日 Copper Ore Processing Methods. The four major steps in the production of marketable copper are mining, concentrating, smelting, and refining. In a few instances, however, leaching takes the place of

China copper flotation plant Manufacturers Factory Suppliers

We are willing to provide Double Roller Crusher, disk separator, Shaking table mineral processing for customers with high quality, appropriate price and good after-sales service.We rely on a complete production line to achieve large-scale production as well as standardization of product image, and to ensure stable quality of copper flotation plant. .

A typical flowsheet used in the flotation process of

Figure 1 shows an example of the most common porphyry copper ore type beneficiation flowsheet. Porphyry ores, although generally contain small amount of copper below 1%, belong to easy-to-float

Design Factory For Processing Copper Ore HN droled

Mekanism Ore Processing Official Feed The Beast Wiki. Dec 13, 2017 A Review on Novel Techniques for Chalcopyrite Ore Processing. 2.2.2.1.1. Intec Copper Process The intec copper process is a proven, patented hydrometallurgical process for the extraction of pure copper and precious metal from sulphide concentrates.

Minerals Special Issue : Recent Advances in Copper Ore

2022年1月28日 Producers, however, are facing challenges due to falling head grades and more complex ore mineralogy. In this Special Issue, recent advances in copper ore processing and extraction are discussed, focusing on: innovations in hydrometallurgical, pyrometallurgical, electrometallurgical, and pre-concentration technologies; improving

Processing of Complex Materials in the Copper

2020年7月6日 A global copper mine-by-mine review undertaken by ICSG found that the global average copper ore grade was as low as 0.45% copper in reported reserves and only 0.65% copper in 2015 copper mine

Optimization of Ore Production in Copper Mine

2020年1月8日 In this feasibility study on optimizing copper ore production, first, we will analyze the copper ore production capacity of the Mujicun copper mine (Hebei province, China) base on the production plans of 3.5 million t/a, 4.5 million t/a, 5.5 million t/a. Then, after the comparison of the three production plans, the op-

Mineral Processing Plant Design, Practice, and Control:

2002年1月1日 However, due to the copper penalties and low-grade molybdenum content of the studied molybdenum concentrate from the Robinson Mine of KGHM Polska Miedz (37.5% molybdenum, 1.59% copper

COPPER FLOTATION PLANT Pineer Mining Machinery

2022年3月1日 OPERATIONPROCESS DESIGN. According to the processing order of the useful mineral, the copper ore processing/mining can be divided into precedence flotation, equivalent flotation, mixed flotation, and partial flotation. Normally 30% T/T deposit in advance, the balance 70% T/T before delivery from the factory. Please Leave

Copper Ore Mining Plant Solution JXSC Machine

2021年12月7日 This JXSC Processing plant Setup is Rock Copper Gravity Separation Plant.Complete set includes Feeding Hopper, Chute Feeder, Rough Jaw crusher, Fine Jaw crusher, Hammer crusher, belt conveyor,

Copper Ore Processing Methods Metallurgist

2017年4月11日 Copper Ore Processing Methods. The four major steps in the production of marketable copper are mining, concentrating, smelting, and refining. In a few instances, however, leaching takes the place of

China copper flotation plant Manufacturers Factory Suppliers

We are willing to provide Double Roller Crusher, disk separator, Shaking table mineral processing for customers with high quality, appropriate price and good after-sales service.We rely on a complete production line to achieve large-scale production as well as standardization of product image, and to ensure stable quality of copper flotation plant. .

A typical flowsheet used in the flotation process of

Figure 1 shows an example of the most common porphyry copper ore type beneficiation flowsheet. Porphyry ores, although generally contain small amount of copper below 1%, belong to easy-to-float

Gold Processing PlantsComplete Ore Process

1 Mineral Processing Plants Gold, Silver, Copper, Zinc, Lead, etc, Ore Default sorting Sort by popularity Sort by latest Sort by price: low to high Sort by price: high to low Showing all 11 results

- Hecho en Indonesia capacidad de 15 toneladas por hari molino de bolas

- concentrador de mineral de planta de oro

- sand trituradoras price in malaysia

- de una trituradora precio

- especificación de fresadora vertical

- fabrica de trompo y zaranda de juguete en venezuela

- 2013 Alta Calidad Trituradora De Cono

- Tipos de trituradora de cono con grasa

- trituracion y cribado de la planta china

- especificaciones de chancadora cnicas

- trituradoras de piedra usadas San Juan de la Maguana

- planta de cribado Sudáfrica

- proceso de mineral de hierro tambor separador iman

- lavado de trituración cribado ppt equipos

- tiendas donde vendan molinos de carne

- molino de bolas Goiânia

- esteras alfombrillas hidrociclón desarenador

- maquina carbon pionero

- Molinos De Rodillos Manuales Mexico Trituradora De Piedra Mojada Por El Oro

- project report pdf single toggle jaw trituradora

- c6 de perforación hidráulica de las cadenas

- pvc pellizco aplastado precios de las materias

- giratoria trituradora 420t producción horaria

- trituradora de piedra portland o

- remedios para quitar el mal de la tierra en la ropa

- chancadoras de latas de sardina

- qué ofreciendo necesidades de arena y grava largos mano

- molinos bola mejores