process of gold ore mining

Gold processing Britannica

gold processing, preparation of the ore for use in various products. For thousands of years the word gold has connoted something of beauty or value. These images are derived

进一步探索Gold Processing MethodsGold Ore Extraction4 Processes To Extract Gold From Its Ore JXSC根据热门内容向你推荐

Gold processing Mining and concentrating Britannica

The nature of the ore deposit determines the mining and mineral processing techniques applied. Oxide ore deposits are frequently of such low grade (e.g., 3 to 10 parts per

进一步探索How to Process Gold ConcentrateEasy Ways to Extract Gold from a Rock (with Pictures) wiki根据热门内容向你推荐

Life cycle assessment of gold production in China

2018年4月1日 In addition, the process of gold ore mining had the highest variation in metal depletion category. Considering the normalization results, improving the utilization

作者: Wei Chen, Yong Geng, Yong Geng, Jinglan Hong, Huijuan Dong, Xiaowei Cui, Mingxing Sun, Qiang Zhang

Gold Mining Process

2021年11月1日 The gold mining process is complex and goes beyond what most people imagine — miners in hard hats working underground or operating large, noisy mining

Gold MiningExtracting gold: the basics, the methods

2023年4月24日 The 3 phases of gold processing. Gold processing generally occurs in three phases: extracting gold from the ground, refining, and manufacturing. Extracting

How to Process Gold Ore? 4 Gold Processing Steps

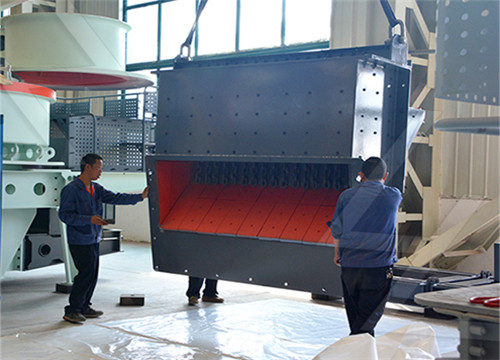

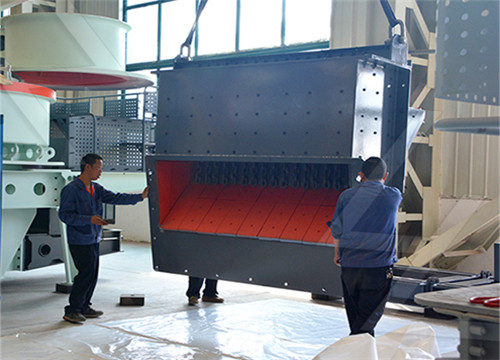

2022年5月19日 01 Step #1: Crushing and Screening. The gold ore crushing process often uses jaw crusher for coarse crushing, standard cone crusher for medium crushing, and

Summary of Gold Plants and Processes ScienceDirect

269 行 2016年1月1日 Table 54.1. Summary of Gold Plants and Flow Sheets Discussed in Gold Ore Processing, Second Edition. Implemented with tube autoclaves 1.5 km long

Ore Processing OceanaGold Waihi Operation Waihi Gold

2023年4月27日 The slurry that remains after this process has a very fine particle size. Typically, 80% of the ore particles are less than 70 microns in size (about the same

8 Types of Gold Ore- Properties and Ways to Process

2023年2月15日 In the arsenopyrite gold mine, the Au content is 72.27%, the Ag content is 27.73%, the As content is 38.79%, the S content is 24.29%, and the Fe content is

Gold processing Mining and concentrating Britannica

The nature of the ore deposit determines the mining and mineral processing techniques applied. Oxide ore deposits are frequently of such low grade (e.g., 3 to 10 parts per million) that extensive mineral processing cannot economically be justified. In this case they are merely shattered by explosives and then piled into heaps for extraction by cyanidation

Life cycle assessment of gold production in China

2018年4月1日 In addition, the process of gold ore mining had the highest variation in metal depletion category. Considering the normalization results, improving the utilization efficiency of electricity, sulfur concentrate, and gold ore should be prioritized for the reduction of overall environmental impacts generated from gold production.

How to Process Gold Ore? 4 Gold Processing Steps

2022年5月19日 01 Step #1: Crushing and Screening. The gold ore crushing process often uses jaw crusher for coarse crushing, standard cone crusher for medium crushing, and short head cone crusher and roll crusher for fine crushing. Most medium and small gold processing plants use two-stage closed-circuit crushing, and large-scale processing

Gold process mineralogy: Objectives,

2004年4月17日 Gold process mineralogy addresses all issues related to gold ore processing by the detailed study of an ore or a mill product. The methodology is widely used as a predictive tool in feasibility

The Mining Process OceanaGold

The Mining Process. Gold at Macraes is known as ‘refractory ore’, which means it is ultra-fine and resistant to the typical cyanide leach process. The mining process at Macraes is circular and follows a cycle of exploration, mining, processing and rehabilitation and closure. With a 30-year history of development spanning fluctuating gold

Ore Processing Challenges in Gold Operation Grinding

2020年6月16日 Ore Processing Challenges in Gold Operation Grinding Circuits. By Scott Ferguson 06.16.2020. Continuous control of the final grinding product size is important to optimize gold liberation for gold milling operations. In addition, the live monitoring of the final product particle size leads to a maximum grinding circuit throughput.

Ore Processing OceanaGold Waihi Operation Waihi Gold

2023年4月27日 The slurry that remains after this process has a very fine particle size. Typically, 80% of the ore particles are less than 70 microns in size (about the same consistency as fine beach sand). Such a fine particle size is required for gold liberation the size required for the cyanide to be able to ‘see’ the gold in the leaching process.

Flow diagram of gold ore processing (Modified

2023年4月26日 The results indicated that the 3-year average of GHGs emissions from factories A to C was 3387 718 kgCO2e per year with approximately 2.92 kgCO2e per ton of granite rock produced over 2012

Review of gold extraction from ores ScienceDirect

1994年10月1日 It can be illustrated that the pre-oxidation of the gold ore by Mn-oxide oxidation controlled Au-extraction efficiency, and with the dissolution of 93.3 % As and 92.5 % Sb from the gold ore in the usage of Mn-oxide-assisted hydrochloric acid oxidation process, it obtains Au extraction ratio of 97.2 % by chlorination leaching.

Artisanal and Small-Scale Gold Mining Without Mercury

2023年1月9日 Concentration means increasing the amount of gold in ore or sediment, by selectively removing lighter particles. This process is mostly used in large scale mining operations but has been increasingly adopted in small scale mining because of its high gold recovery rate and low cost. The best practices for chemical leaching are a combination

Gold processing Mining and concentrating Britannica

The nature of the ore deposit determines the mining and mineral processing techniques applied. Oxide ore deposits are frequently of such low grade (e.g., 3 to 10 parts per million) that extensive mineral processing cannot economically be justified. In this case they are merely shattered by explosives and then piled into heaps for extraction by cyanidation

Life cycle assessment of gold production in China

2018年4月1日 2.3. Data sources. The LCI of gold production shown in Table 1 are collected based on the annual monitoring data of a gold production company located in Qinghai Province of China. The background data of each material production used for gold production are obtained from the Chinese process-based LCI database (CPLCID), in

How to Process Gold Ore? 4 Gold Processing Steps

2022年5月19日 01 Step #1: Crushing and Screening. The gold ore crushing process often uses jaw crusher for coarse crushing, standard cone crusher for medium crushing, and short head cone crusher and roll crusher for fine crushing. Most medium and small gold processing plants use two-stage closed-circuit crushing, and large-scale processing

Gold process mineralogy: Objectives,

2004年4月17日 Gold process mineralogy addresses all issues related to gold ore processing by the detailed study of an ore or a mill product. The methodology is widely used as a predictive tool in feasibility

The Mining Process OceanaGold

The Mining Process. Gold at Macraes is known as ‘refractory ore’, which means it is ultra-fine and resistant to the typical cyanide leach process. The mining process at Macraes is circular and follows a cycle of exploration, mining, processing and rehabilitation and closure. With a 30-year history of development spanning fluctuating gold

Ore Processing Challenges in Gold Operation Grinding

2020年6月16日 Ore Processing Challenges in Gold Operation Grinding Circuits. By Scott Ferguson 06.16.2020. Continuous control of the final grinding product size is important to optimize gold liberation for gold milling operations. In addition, the live monitoring of the final product particle size leads to a maximum grinding circuit throughput.

Ore Processing OceanaGold Waihi Operation Waihi Gold

2023年4月27日 The slurry that remains after this process has a very fine particle size. Typically, 80% of the ore particles are less than 70 microns in size (about the same consistency as fine beach sand). Such a fine particle size is required for gold liberation the size required for the cyanide to be able to ‘see’ the gold in the leaching process.

Creating the zero-carbon mine McKinsey

2021年6月29日 The following analysis is focused on the mining of metals (copper, gold, iron ore, and so on) and excludes coal and fugitive methane. Breakdown of current mining emissions Emissions within mining can be broken down into three broad types: Scope 1 (emissions from diesel), Scope 2 (emissions from electricity generation), and Scope 3

Flow diagram of gold ore processing (Modified

2023年4月26日 The results indicated that the 3-year average of GHGs emissions from factories A to C was 3387 718 kgCO2e per year with approximately 2.92 kgCO2e per ton of granite rock produced over 2012

Review of gold extraction from ores ScienceDirect

1994年10月1日 It can be illustrated that the pre-oxidation of the gold ore by Mn-oxide oxidation controlled Au-extraction efficiency, and with the dissolution of 93.3 % As and 92.5 % Sb from the gold ore in the usage of Mn-oxide-assisted hydrochloric acid oxidation process, it obtains Au extraction ratio of 97.2 % by chlorination leaching.

-

iChancadoras html soluciones com trituradora de piedra

-

el tratamiento relacion

-

canteras de piedra en tolu

-

deber fabricante trituradora

-

construccion de casas caba241as llave en mano precios

-

Trituradoras Maquinas

-

mineria molinos de martillos usados rrpara la venta

-

maquinaria para mineria en colombia

-

máquinas trituradoras de piedra usadas en sudáfrica

-

vendo planta flotacion minerales colombia

-

equipo para planta de trituración de piedra méxico

-

magnetico separador trituradora

-

como molino de bentonita de sodio

-

equipos de planta de cemento en tamilnadu

-

maquinaria para fundicion en colombia

-

Panamericano Metan Hierrromolino

-

piedras chancadora de quijadas de la venta

-

molino de quijadas marca torrey mod m

-

molinos maiz trituradoras

-

trituradora de hormigón para alquilar en los angeles

- c6 de perforación hidráulica de las cadenas

- pvc pellizco aplastado precios de las materias

- giratoria trituradora 420t producción horaria

- trituradora de piedra portland o

- remedios para quitar el mal de la tierra en la ropa

- chancadoras de latas de sardina

- qué ofreciendo necesidades de arena y grava largos mano

- molinos bola mejores

Gold processing Mining and concentrating Britannica

The nature of the ore deposit determines the mining and mineral processing techniques applied. Oxide ore deposits are frequently of such low grade (e.g., 3 to 10 parts per

Life cycle assessment of gold production in China

2018年4月1日 In addition, the process of gold ore mining had the highest variation in metal depletion category. Considering the normalization results, improving the utilization

Gold Mining Process

2021年11月1日 The gold mining process is complex and goes beyond what most people imagine — miners in hard hats working underground or operating large, noisy mining

Gold MiningExtracting gold: the basics, the methods

2023年4月24日 The 3 phases of gold processing. Gold processing generally occurs in three phases: extracting gold from the ground, refining, and manufacturing. Extracting

How to Process Gold Ore? 4 Gold Processing Steps

2022年5月19日 01 Step #1: Crushing and Screening. The gold ore crushing process often uses jaw crusher for coarse crushing, standard cone crusher for medium crushing, and

Summary of Gold Plants and Processes ScienceDirect

269 行 2016年1月1日 Table 54.1. Summary of Gold Plants and Flow Sheets Discussed in Gold Ore Processing, Second Edition. Implemented with tube autoclaves 1.5 km long

Ore Processing OceanaGold Waihi Operation Waihi Gold

2023年4月27日 The slurry that remains after this process has a very fine particle size. Typically, 80% of the ore particles are less than 70 microns in size (about the same

8 Types of Gold Ore- Properties and Ways to Process

2023年2月15日 In the arsenopyrite gold mine, the Au content is 72.27%, the Ag content is 27.73%, the As content is 38.79%, the S content is 24.29%, and the Fe content is

Gold processing Mining and concentrating Britannica

The nature of the ore deposit determines the mining and mineral processing techniques applied. Oxide ore deposits are frequently of such low grade (e.g., 3 to 10 parts per million) that extensive mineral processing cannot economically be justified. In this case they are merely shattered by explosives and then piled into heaps for extraction by cyanidation

Life cycle assessment of gold production in China

2018年4月1日 In addition, the process of gold ore mining had the highest variation in metal depletion category. Considering the normalization results, improving the utilization efficiency of electricity, sulfur concentrate, and gold ore should be prioritized for the reduction of overall environmental impacts generated from gold production.

How to Process Gold Ore? 4 Gold Processing Steps

2022年5月19日 01 Step #1: Crushing and Screening. The gold ore crushing process often uses jaw crusher for coarse crushing, standard cone crusher for medium crushing, and short head cone crusher and roll crusher for fine crushing. Most medium and small gold processing plants use two-stage closed-circuit crushing, and large-scale processing

Gold process mineralogy: Objectives,

2004年4月17日 Gold process mineralogy addresses all issues related to gold ore processing by the detailed study of an ore or a mill product. The methodology is widely used as a predictive tool in feasibility

The Mining Process OceanaGold

The Mining Process. Gold at Macraes is known as ‘refractory ore’, which means it is ultra-fine and resistant to the typical cyanide leach process. The mining process at Macraes is circular and follows a cycle of exploration, mining, processing and rehabilitation and closure. With a 30-year history of development spanning fluctuating gold

Ore Processing Challenges in Gold Operation Grinding

2020年6月16日 Ore Processing Challenges in Gold Operation Grinding Circuits. By Scott Ferguson 06.16.2020. Continuous control of the final grinding product size is important to optimize gold liberation for gold milling operations. In addition, the live monitoring of the final product particle size leads to a maximum grinding circuit throughput.

Ore Processing OceanaGold Waihi Operation Waihi Gold

2023年4月27日 The slurry that remains after this process has a very fine particle size. Typically, 80% of the ore particles are less than 70 microns in size (about the same consistency as fine beach sand). Such a fine particle size is required for gold liberation the size required for the cyanide to be able to ‘see’ the gold in the leaching process.

Flow diagram of gold ore processing (Modified

2023年4月26日 The results indicated that the 3-year average of GHGs emissions from factories A to C was 3387 718 kgCO2e per year with approximately 2.92 kgCO2e per ton of granite rock produced over 2012

Review of gold extraction from ores ScienceDirect

1994年10月1日 It can be illustrated that the pre-oxidation of the gold ore by Mn-oxide oxidation controlled Au-extraction efficiency, and with the dissolution of 93.3 % As and 92.5 % Sb from the gold ore in the usage of Mn-oxide-assisted hydrochloric acid oxidation process, it obtains Au extraction ratio of 97.2 % by chlorination leaching.

Artisanal and Small-Scale Gold Mining Without Mercury

2023年1月9日 Concentration means increasing the amount of gold in ore or sediment, by selectively removing lighter particles. This process is mostly used in large scale mining operations but has been increasingly adopted in small scale mining because of its high gold recovery rate and low cost. The best practices for chemical leaching are a combination

Gold processing Mining and concentrating Britannica

The nature of the ore deposit determines the mining and mineral processing techniques applied. Oxide ore deposits are frequently of such low grade (e.g., 3 to 10 parts per million) that extensive mineral processing cannot economically be justified. In this case they are merely shattered by explosives and then piled into heaps for extraction by cyanidation

Life cycle assessment of gold production in China

2018年4月1日 2.3. Data sources. The LCI of gold production shown in Table 1 are collected based on the annual monitoring data of a gold production company located in Qinghai Province of China. The background data of each material production used for gold production are obtained from the Chinese process-based LCI database (CPLCID), in

How to Process Gold Ore? 4 Gold Processing Steps

2022年5月19日 01 Step #1: Crushing and Screening. The gold ore crushing process often uses jaw crusher for coarse crushing, standard cone crusher for medium crushing, and short head cone crusher and roll crusher for fine crushing. Most medium and small gold processing plants use two-stage closed-circuit crushing, and large-scale processing

Gold process mineralogy: Objectives,

2004年4月17日 Gold process mineralogy addresses all issues related to gold ore processing by the detailed study of an ore or a mill product. The methodology is widely used as a predictive tool in feasibility

The Mining Process OceanaGold

The Mining Process. Gold at Macraes is known as ‘refractory ore’, which means it is ultra-fine and resistant to the typical cyanide leach process. The mining process at Macraes is circular and follows a cycle of exploration, mining, processing and rehabilitation and closure. With a 30-year history of development spanning fluctuating gold

Ore Processing Challenges in Gold Operation Grinding

2020年6月16日 Ore Processing Challenges in Gold Operation Grinding Circuits. By Scott Ferguson 06.16.2020. Continuous control of the final grinding product size is important to optimize gold liberation for gold milling operations. In addition, the live monitoring of the final product particle size leads to a maximum grinding circuit throughput.

Ore Processing OceanaGold Waihi Operation Waihi Gold

2023年4月27日 The slurry that remains after this process has a very fine particle size. Typically, 80% of the ore particles are less than 70 microns in size (about the same consistency as fine beach sand). Such a fine particle size is required for gold liberation the size required for the cyanide to be able to ‘see’ the gold in the leaching process.

Creating the zero-carbon mine McKinsey

2021年6月29日 The following analysis is focused on the mining of metals (copper, gold, iron ore, and so on) and excludes coal and fugitive methane. Breakdown of current mining emissions Emissions within mining can be broken down into three broad types: Scope 1 (emissions from diesel), Scope 2 (emissions from electricity generation), and Scope 3

Flow diagram of gold ore processing (Modified

2023年4月26日 The results indicated that the 3-year average of GHGs emissions from factories A to C was 3387 718 kgCO2e per year with approximately 2.92 kgCO2e per ton of granite rock produced over 2012

Review of gold extraction from ores ScienceDirect

1994年10月1日 It can be illustrated that the pre-oxidation of the gold ore by Mn-oxide oxidation controlled Au-extraction efficiency, and with the dissolution of 93.3 % As and 92.5 % Sb from the gold ore in the usage of Mn-oxide-assisted hydrochloric acid oxidation process, it obtains Au extraction ratio of 97.2 % by chlorination leaching.

- iChancadoras html soluciones com trituradora de piedra

- el tratamiento relacion

- canteras de piedra en tolu

- deber fabricante trituradora

- construccion de casas caba241as llave en mano precios

- Trituradoras Maquinas

- mineria molinos de martillos usados rrpara la venta

- maquinaria para mineria en colombia

- máquinas trituradoras de piedra usadas en sudáfrica

- vendo planta flotacion minerales colombia

- equipo para planta de trituración de piedra méxico

- magnetico separador trituradora

- como molino de bentonita de sodio

- equipos de planta de cemento en tamilnadu

- maquinaria para fundicion en colombia

- Panamericano Metan Hierrromolino

- piedras chancadora de quijadas de la venta

- molino de quijadas marca torrey mod m

- molinos maiz trituradoras

- trituradora de hormigón para alquilar en los angeles

- c6 de perforación hidráulica de las cadenas

- pvc pellizco aplastado precios de las materias

- giratoria trituradora 420t producción horaria

- trituradora de piedra portland o

- remedios para quitar el mal de la tierra en la ropa

- chancadoras de latas de sardina

- qué ofreciendo necesidades de arena y grava largos mano

- molinos bola mejores