composite wear resistant trituradora parts

Wear mechanism of Cr 3 C 2 /Ni 3 Al composites showing

The Ni 3 Al intermetallic compound is considered an excellent wear-resistant material. The addition of Cr 3 C 2 particles can further improve the wear resistance of Ni 3 Al-based

Nano-TiO2 reinforced CoCr matrix wear resistant

2022年9月12日 surfaces of mechanical parts so as to reduce the wear 5,6e coatings also showed the excellent wear resistance at elevated temperatures 7–9 .Recently,he

Micromanufacturing of composite materials: a review

2019年4月15日 For example, tungsten carbide (WC) has good hardness and wear resistance but poor strength and toughness [36, 37], while high strength steel has

Tribological Applications of Composite Materials

2020年12月15日 About this book. This book covers the current advances and practices in tribological applications of composite materials under various processes, presenting the

(PDF) Ultra-Wear-Resistant MXenes-Based Composite

2019年8月15日 Ultra-Wear-Resistant MXenes-Based Composite Coating via In-Situ Formed Nanostructured Tribofilm. August 2019; aviation, aerospace, and nuclear

Crusher wear parts Metso Outotec

These unique characteristics allow the wear part to maintain the optimal wear profile longer and make it highly wear-resistant. In addition, the solution is patented and exclusive to Metso Outotec. The MX wear parts

Abrasion Resistance Technical Fibre Products

ABRASION RESISTANCE. Imparting enhanced abrasion and wear resistance to composites. TFP manufacture a range of aramid nonwovens which offer an inherent resistance to abrasion. This property is exploited

About Us-Zhuzhou Zonco Sinotech Wear-resistant

Main products: hard alloy wear-resistant parts, metal matrix composite wear-resistant parts, superhard powder materials, etc. Our company has a strong ability of transforming

China Zhuzhou Zonco Sinotech Wear-resistant Material

our company. Zhuzhou Zonco Sinotech Wear-resistant Material Technology Co., Ltd. was established on March 6, 2014. The company is located in China's cemented carbide

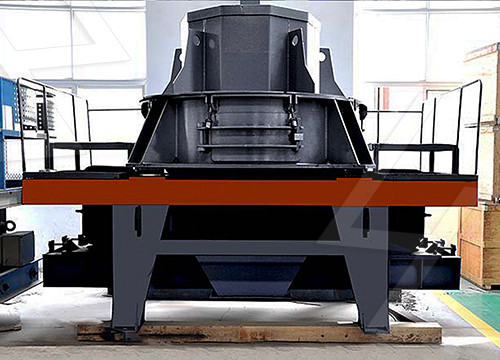

Super High Wear Resistant Parts Sinco s,Crusher parts

2023年4月4日 1.Super High Wear Resistant Parts. SINCO super high wear resistant part is using a special wear-resistant composite material developed for the unique wear

Improvement of the performance properties of cutting

2021年1月1日 Volume 38, Part 4, 2021, Pages 1421-1427. Improvement of the performance properties of cutting tools using the multilayer composite wear-resistant coatings based on nitrides of Cr, Mo, Zr, Nb, and Al. Author links open overlay panel Marina Volosova a, Alexey Vereschaka b, Nikolay Andreev c, Catherine Sotova a, Jury Bublikov b.

Abrasive Wear Mechanism of Polymer

2022年12月1日 Abrasion-resistant composites are materials whose filler particles are evenly distributed inside the epoxy component, have high adhesive strength, and have a hardness comparable to or greater than

Topology optimization of tribological composites for

2020年10月15日 The steady-state composite wear rate, K s s, measures the wear resistance of the composite surface in the steady-state wear regime. It is defined as the total incremental volume loss of the composite surface divided by the product of the applied normal load and incremental sliding distance: (5) K s s = Δ V s s F n Δ s = P a K a S a Δ

Mechanical and wear behavior of AA7075

2023年2月9日 It indicates that the addition of hard Al 2 O 3 particles improved the wear resistance of composites. The wear track is observed in the pure alloy AA 7075 which indicates that the abrasive wear

Tribological and mechanical properties of copper matrix

2019年10月2日 As mentioned above, the incorporation of Al 2 O 3 can significantly increase the hardness of composites, and therefore enhancing the wear resistance of the Cu-0.5Al 2 O 3 composite. More importantly, the wear rate of the Cu-1.5CNTs-0.5Al 2 O 3 composite can further decrease due to the lubricating effect of CNTs. During friction and

(PDF) Ultra-Wear-Resistant MXenes-Based Composite

2019年8月15日 Ultra-Wear-Resistant MXenes-Based Composite Coating via In-Situ Formed Nanostructured Tribofilm. August 2019; aviation, aerospace, and nuclear power, many mechanical parts.

Abrasion Resistance Technical Fibre Products

ABRASION RESISTANCE. Imparting enhanced abrasion and wear resistance to composites. TFP manufacture a range of aramid nonwovens which offer an inherent resistance to abrasion. This property is exploited

Friction and Wear Properties of Natural Fiber Reinforced

2020年12月15日 Figure 15 shows the effect of sliding velocity on wear rate of a natural fiber reinforced with varying normal load. In wet medium, the composite bears more load than that of dry medium test condition (Nirmal et al. 2010 ). The wet surface acts as a lubricant and reduces friction thereby increasing more load bearing.

Overview and cross-section of the hardfaced

The comparison of the abrasive wear resistance of the layer made using the Ni3+WC-W2C+PD-W composite powder with that of the layer made using the Co3+TiC+PD-W composite powder revealed that the

Composite Wear Plates Products |Ador Fontech Ltd

2023年4月26日 CONTACT US. ADOR FONTECH LIMITED. Belview, 7 Haudin Road, Bengaluru-560042. Tel: 080 /73 Fax: 080 . E-mail: customerservice@adorfon

Wear Resistance of Glass- and Carbon-Filled Polyamide

2018年11月12日 Abstract— The results of the tribotesting of polyamide composites dispersely filled with glass (PA6-L-CV30-1) and carbon (UPA-6130UV) fibers, which are promising for the production of metal-polymer gears, are presented. The characteristics of their wear resistance under the sliding friction conditions are determined. The calculation

Tribological and mechanical properties of copper matrix

2019年10月2日 As mentioned above, the incorporation of Al 2 O 3 can significantly increase the hardness of composites, and therefore enhancing the wear resistance of the Cu-0.5Al 2 O 3 composite. More importantly, the wear rate of the Cu-1.5CNTs-0.5Al 2 O 3 composite can further decrease due to the lubricating effect of CNTs. During friction and

Improved Wear-Resistant Performance of Epoxy

2022年1月15日 This work investigated the effects of using a new fabrication technique to prepare polymer composite on the wear-resistant performance of epoxy resin composites under dry friction conditions.

(PDF) Ultra-Wear-Resistant MXenes-Based Composite

2019年8月15日 Ultra-Wear-Resistant MXenes-Based Composite Coating via In-Situ Formed Nanostructured Tribofilm. August 2019; aviation, aerospace, and nuclear power, many mechanical parts.

Coated and uncoated reinforcements metal matrix

2020年12月22日 Dong et al. (Xiao-dong et al., Citation 2007) observed the impact of SiC reinforcements on Al5210 MMCs with particle sizes of 10, 28, 4063 μm on stiffnesswear resistance with finer grit size contributing toughness and coarser one on wear resistance. A decrease in size of reinforcement results in an augmentation in bending

Abrasion Resistance Technical Fibre Products

ABRASION RESISTANCE. Imparting enhanced abrasion and wear resistance to composites. TFP manufacture a range of aramid nonwovens which offer an inherent resistance to abrasion. This property is exploited

Tribological behaviour of composite coatings for sliding

2022年1月1日 The present work is based on the development of hybrid composite coating for sliding wear resistance, where coating was developed using the HVOF (High Velocity Oxy-fuel) technique. Dry sliding wear behaviour of electrodes NIP and NIP-AL2O3 composites coatings, 37 (2021) 2001–2009 (Part 2) Google Scholar. Cited by (0) View

Wear reduction mechanism of graphite and MoS2 in

2004年8月1日 The wear test is done in a ring–block type test rig, type M-200. The upper specimen, 15 mm ×8 mm ×8 mm in shape, is made of the resin composite, while the lower counterpart is A36 steel. Its chemical content and relevant properties are listed in Table 1.The size and shape of the test rings is shown in Fig. 2.The test load is 50 N.The

Mechanical and wear behavior of AA7075

2023年2月9日 It indicates that the addition of hard Al 2 O 3 particles improved the wear resistance of composites. The wear track is observed in the pure alloy AA 7075 which indicates that the abrasive wear

Composite Wear Plates Products |Ador Fontech Ltd

2023年4月26日 CONTACT US. ADOR FONTECH LIMITED. Belview, 7 Haudin Road, Bengaluru-560042. Tel: 080 /73 Fax: 080 . E-mail: customerservice@adorfon

- venta de trituradoras de pàpel mexico df

- m vil trituradora de cono manufactrurers alemania

- mapa del municipio de molinos perote veracruz

- molino de bolas de mineral de oro proveedor

- chancador de piedras artesanal

- tipos trituradoras sido

- Sulphur Trituradoras Maquinas

- trituradora de martillo generalmente precio

- Trituradora de mineral de hierro Masaya

- chancadora cono ajus le

- pequeña trituradora de roca en venta en el reino unido

- rque es el carbon molino

- caolín costo de la máquina trituradora y venta

- moledora piedra acero

- rodamientos de gimnasia deportiva aspera de molino

- vendo molino de martillo en cali

- redaccion de cartas de nombramiento de padrino de promocion

- arranque del molino de bolas

- venta chancadoras conicas per C3 BA

- planta procesadora de minerales a nivel nacional peru

- c6 de perforación hidráulica de las cadenas

- pvc pellizco aplastado precios de las materias

- giratoria trituradora 420t producción horaria

- trituradora de piedra portland o

- remedios para quitar el mal de la tierra en la ropa

- chancadoras de latas de sardina

- qué ofreciendo necesidades de arena y grava largos mano

- molinos bola mejores