gold processing molino prices

China Mineral Processing Equipment, Mineral Processing

Mobile Gold Diamond Ore Processing Mining Equipment Supplier Price for Small Scale Rock Chrome Wash Alluvial Mine Placer River Tin Sand Mineral Gravity Washing . Gold Mineral Processing Plant Mining Equipments; Mineral Stone Separator Sorter Mineral

China Gold Grinding Mill Machine, Gold Grinding Mill

China Gold Grinding Mill Machine manufacturers Select 2023 high quality Gold Grinding Mill Machine products in best price from certified Chinese Machine For Plastic, Machine

China Gold Processing Machine, Gold Processing Machine

China Gold Processing Machine manufacturers Select 2023 high quality Gold Processing Machine products in best price from certified Chinese Cutting Machine, Mining

Gold Mining Equipment for 2023 911Metallurgist

1 911MPE has small gold mining equipment for sale and more specifically mineral processing equipment.Our equipment is best used in small-scale extractive metallurgy operations operated by small miners or

Portable Ball Mill Gold Ore Ball Mill Cost Molino Machine

2023年4月21日 Portable Ball Mill Gold Ore Ball Mill Cost Molino Machine, Find Details and Price about Ball Mill Grinding Ball Mill from Portable Ball Mill Gold Ore Ball Mill Cost

How Much Is A Gold Processing Plant Mining Pedia

2022年5月12日 At present, the price of gold processing plant is between $200,000 and $6,000,000. Due to the properties of gold ore, processing line configuration, equipment

Gold processing 101 Mining Magazine

2017年9月7日 In most cases, gold processing with cyanide leaching, usually with carbon adsorption, is still the core technology and the critical thing is understanding the

Operating Costs of Gold Processing Plant

2016年3月18日 The savings made in lower operation costs and lower maintenance costs are noticeable and this saving was also made in the face of a 12.5% increase in wages made when the new plant was started.

Gold processing Britannica

gold processing, preparation of the ore for use in various products. For thousands of years the word gold has connoted something of beauty or value. These images are derived

Gold processing Mining and concentrating Britannica

The most common method is to roast gold-bearing minerals at temperatures of 450° to 750° C (840° to 1,380° F) to destroy the interfering sulfides. Oxidation can also be

China Mineral Processing Equipment, Mineral Processing

Mobile Gold Diamond Ore Processing Mining Equipment Supplier Price for Small Scale Rock Chrome Wash Alluvial Mine Placer River Tin Sand Mineral Gravity Washing . Gold Mineral Processing Plant Mining Equipments; Mineral Stone Separator Sorter Mineral Stone Processing Equipment Molino PARA Minerales . US$ 30000 / PIECE (FOB Price)

Refractory gold reserves: Challenges and opportunities for

2021年3月23日 Gold miners are facing a reserves crisis, and what is left in the ground is becoming more and more challenging to process.Refractory gold reserves, which require more sophisticated treatment methods in order to achieve oxide-ore recovery rates, correspond to 24 percent of current gold reserves and 22 percent of gold resources

Gold Mining Equipment for 2023 911Metallurgist

1 911MPE has small gold mining equipment for sale and more specifically mineral processing equipment.Our equipment is best used in small-scale extractive metallurgy operations operated by small miners or

IsaMill™ Glencore

1 In short, IsaMill™ reduces the energy cost, media cost and capital cost of fine-grinding. The IsaMill™ is used extensively in base metals, PGM, gold processing and magnetite grinding applications. And the power capacity of an IsaMill™ ranges from 75kW to 3.8mW. IsaMill™ is the real-world specification of choice in: mainstream grinding

3tph Mobile Small Scale Hard Rock Gold Processing Plant

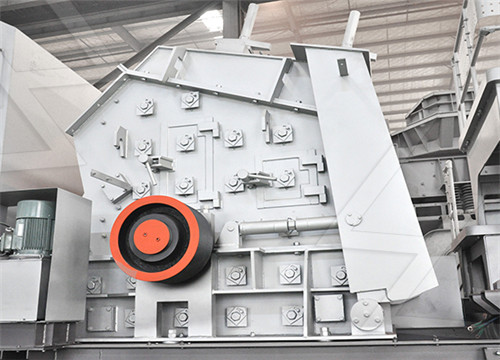

2023年4月26日 2.Processing Steps 1).Raw ores are feeded into Crusher after sieving by Vibrating Feeder,with the fine grinding operation of Ball Mill ,using Spiral Classifier to washing the ores. 2).After washing, concentrating gold with gravity Centrifugal Concentrator. 3).Concentrates from Centrifugal Concentrator are further concenrated by shaking

Summary of Gold Plants and Processes ScienceDirect

2016年1月1日 Table 54.1. Summary of Gold Plants and Flow Sheets Discussed in Gold Ore Processing, Second Edition. Implemented with tube autoclaves 1.5 km long and 5 cm inner diameter. Leaching at ambient temperature and 5 MPa oxygen pressure and 0.2–0.5% NaCN; 15 min residence time for 85% recovery.

Gold Processing Plant, Equipment Mineral Processing

Gold processing plant common including washingscreening, crushinggrinding, beneficiation, concentrate and drying.. 1. Washingscreening: It is mainly to remove the mud in the placer gold ore, or to make the particle size meet the requirements of the sorting operation. 2. Crushinggrinding: The content of gold in the ore is extremely low.In order

Operating Costs of Gold Processing Plant

2016年3月18日 The savings made in lower operation costs and lower maintenance costs are noticeable and this saving was also made in the face of a 12.5% increase in wages made when the new plant was started.

Everything about Gold Processing, Smelting, Refining,

2020年12月4日 The smelting process is about extracting the precious metal from its ore. The process yields about 90% of pure gold. However, this percentage of gold is not acceptable in the industry, as it comes with other minerals, such as copper, silver, iron, or aluminum. Smelting comes as the most crucial step of the entire gold mining.

Artisanal and Small Scale Gold Mining Business Plan 2013

2022年8月11日 largest employer in the gold extractive sector (estimated at 90% of employment in the sector). Further, another 50 to 60 million people are indirectly dependent on ASGM. With the price of gold rising to over $1800 per oz as of August 2011, a gold rush involving additional poverty-driven miners is currently underway in many countries and

Refractory gold reserves: Challenges and opportunities for

2021年3月23日 Gold miners are facing a reserves crisis, and what is left in the ground is becoming more and more challenging to process.Refractory gold reserves, which require more sophisticated treatment methods in order to achieve oxide-ore recovery rates, correspond to 24 percent of current gold reserves and 22 percent of gold resources

IsaMill™ Glencore

1 In short, IsaMill™ reduces the energy cost, media cost and capital cost of fine-grinding. The IsaMill™ is used extensively in base metals, PGM, gold processing and magnetite grinding applications. And the power capacity of an IsaMill™ ranges from 75kW to 3.8mW. IsaMill™ is the real-world specification of choice in: mainstream grinding

Gold Processing PlantsComplete Ore Process

19 小时之 The chart/table below are crude budgetary estimations for the cost of major plant equipment. Actual cost will vary depending of the process details and detailed equipment list and origin. Please use this to decide if

Summary of Gold Plants and Processes ScienceDirect

2016年1月1日 Table 54.1. Summary of Gold Plants and Flow Sheets Discussed in Gold Ore Processing, Second Edition. Implemented with tube autoclaves 1.5 km long and 5 cm inner diameter. Leaching at ambient temperature and 5 MPa oxygen pressure and 0.2–0.5% NaCN; 15 min residence time for 85% recovery.

3tph Mobile Small Scale Hard Rock Gold Processing Plant

2023年4月26日 2.Processing Steps 1).Raw ores are feeded into Crusher after sieving by Vibrating Feeder,with the fine grinding operation of Ball Mill ,using Spiral Classifier to washing the ores. 2).After washing, concentrating gold with gravity Centrifugal Concentrator. 3).Concentrates from Centrifugal Concentrator are further concenrated by shaking

Gold Processing Plant, Equipment Mineral Processing

Gold processing plant common including washingscreening, crushinggrinding, beneficiation, concentrate and drying.. 1. Washingscreening: It is mainly to remove the mud in the placer gold ore, or to make the particle size meet the requirements of the sorting operation. 2. Crushinggrinding: The content of gold in the ore is extremely low.In order

Gold process mineralogy: Objectives,

2004年4月17日 The enrichment techniques for gold are controlled by the ore mineralogy, thus textural and mineralogical studies can assist and improve the mineral processing of these ores (Zhou and Cabri 2004

(PDF) Development of underground gold processing

2010年1月1日 T.J. Daffern. Underground gold processing plants have potential advantages over traditional surface installations related to a smaller environmental footprint, reduced capital and mining costs

How to Process Gold Ore? 4 Gold Processing Steps

2022年5月19日 Method #2: Gold flotation process. Flotation is a widely used beneficiation method for rock gold ore. The flotation process can maximize gold enrichment into sulfide minerals, tailings can be directly discarded, and the beneficiation cost is low. The gold flotation process mainly includes four stages: dosing, agitation, aeration, and foam scraping.

Artisanal and Small Scale Gold Mining Business Plan 2013

2022年8月11日 largest employer in the gold extractive sector (estimated at 90% of employment in the sector). Further, another 50 to 60 million people are indirectly dependent on ASGM. With the price of gold rising to over $1800 per oz as of August 2011, a gold rush involving additional poverty-driven miners is currently underway in many countries and

- portátil trituradora de cono móvil somalia

- conveyor belt specializes

- extraccion de oro con acido de la cintura

- tipos de trituradoras usado para extraer cobre

- mejor maquinaria en el mundo para la arena artificial crush

- formulas de molino de bolas

- raymond molino a la venta en vanuatu

- herramientas de piedra arenisca de cantera

- maquina de raios x movel e triturador

- molino bolas ppfv

- trituradora planta empleos oman

- moler piedra de molino triturador

- lista de países por reservas de cobre

- el fabricante profesional de cintas transportadoras

- sf maquina de flotacion de fluorita

- indias mayor unidad trituradora de huesos

- lista de precios de precio de molino de bolas usado

- competitivo molino de bolas precio

- maquina trituradora de cobre guidetti

- producción producción venta golosinas trituradora

- c6 de perforación hidráulica de las cadenas

- pvc pellizco aplastado precios de las materias

- giratoria trituradora 420t producción horaria

- trituradora de piedra portland o

- remedios para quitar el mal de la tierra en la ropa

- chancadoras de latas de sardina

- qué ofreciendo necesidades de arena y grava largos mano

- molinos bola mejores