energy consumption of crushing machine

Study of the Energy-Power Parameters of the Crushing

2023年3月6日 As experience shows, when one determines the energy-power parameters of crushing and grinding processes by using the existing methods, the power of motors used in drives of existing crushers of various types often turns out to be excessive [10, 11].In

Predicting the overall specific energy requirement of

2009年5月1日 The total specific energy (W T) to reduce in size primary crusher product to final product is given by: (3) W T = W a + W b + W c + W h + W s where. W a = specific

Energy consumption in machining: Classification,

2017年8月15日 So the specific energy consumption is used to predict the machine tool energy consumption during cutting usually. Diaz et al. developed a predictive model for

Optimal energy control of a crushing process based on

2016年1月15日 1. Introduction. Vertical shaft impact (VSI) crushers are processing machines which are usually used in tertiary crushing stations of both aggregate and

(PDF) Analysis of Energy Consumption of Crushing

2017年1月27日 Due to the inefficiency of the jaw crushing machine, whose no-load power consumption is between 40 and 50% of its rated power, the optimal switching control

Table 6 Energy consumption values of each crusher per

For the sedimentary rocks (Siltstone) the specific crushing energy is approximately 1.26 kJ/kg. Tosun and Konak (2014) measured power consumption of jaw crusher during

Crushing Energy Efficiency North American Mining

2021年6月10日 Indeed, innovation to reduce energy consumption in comminution is considered significant enough to be the focus of Natural Resources Canada’s Crush It!

Drive power calculation of a crushing machine working

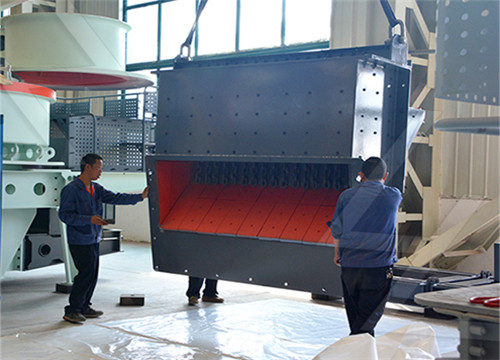

Energy consumption for crushing various materials makes up a large share (up to 5%) in the energy balance of the world. Many industrial industries, including mining, process large

Optimal energy management for a jaw crushing process in

2014年4月15日 Hence, through the simulation results, it is shown that, unlike the VL-based optimal controller, the optimal switching controller has a greater potential to achieve high

Crushing EnergyWork of Crushing Machines

2016年3月5日 “The single unit is a Nissen stamp of 1659 lb., 7½-in. drop at 100 per minute crushing 5½ tons per stamp per day through a 40-mesh screen. The 5-stamp unit is a fast crushing [design, 1250 lb., 7½-in. drop,

Study of the Energy-Power Parameters of the Crushing

2023年3月6日 As experience shows, when one determines the energy-power parameters of crushing and grinding processes by using the existing methods, the power of motors used in drives of existing crushers of various types often turns out to be excessive [10, 11].In this case, the drive will operate at a relatively low load (ratio of the power consumed by the

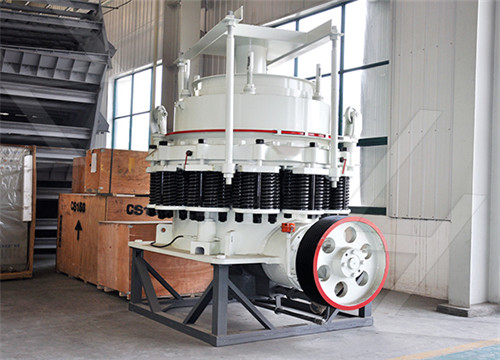

Influence of Operating Conditions and Crushing Chamber

2018年5月1日 This stone provides an energy consumption model and explains how the operating conditions and structural parameters of a crushing chamber affect energy consumption. Energy consumption is closely related to compressive pressure and displacement. The relationship between pressure, displacement and structural

Optimal energy control of a crushing process based on

2016年1月15日 1. Introduction. Vertical shaft impact (VSI) crushers are processing machines which are usually used in tertiary crushing stations of both aggregate and mining industries for crushing of hard rock material or ores when a product material with cubical shape and large amount of fines is required [1], [2].When compared to other tertiary

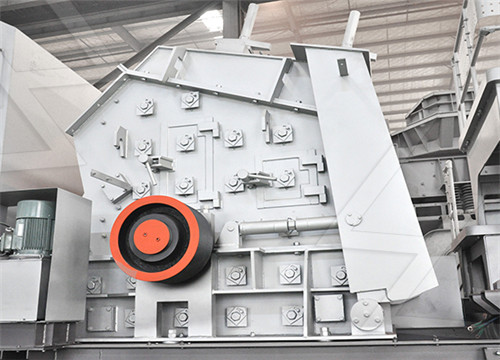

ANALYSIS OF ENERGY CONSUMPTION OF CRUSHING

crushing for er = 24 mm and 11 mm. In the tests special design of variable profile moving jaw was used and fixed jaw was flat. The analysis of the results shows that taking into account energy consumption, it is better to use two-stage crushing process. For given materials energy consumption in the two-stage crushing process was reduced by 30%.

Prospects for Energy-Saving Methods of Crushing Brittle

2021年10月4日 Abstract Crushing machines are part of the charge departments of blast-furnace and steel-making shops of metallurgical enterprises. One of the main indicator of the crushing process is its energy efficiency. It is determined by the mass of crushed material when consuming a unit of electricity. The article considers various methods of crushing

A review of modeling and control strategies for cone

2021年8月15日 It was shown that the control strategy maximizes the crushing energy utilization, prolongs the lifetime of the crusher parts, and increases the crushing efficiency. Hulthén and Evertsson (2009) described the implementation of a naive pathfinder finite state machine using online measurements of the CSS to control the crushing performance.

Energy consumption to crush a metric ton of material at

Looking at Figure 12, using a closed side setting of 110-120mm, has an energy consumption in crushing of approximately 1080 megajoules (MJ) per metric tonne and a total energy consumption of

Drive power calculation of a crushing machine working

Energy consumption for crushing various materials makes up a large share (up to 5%) in the energy balance of the world. Many industrial industries, including mining, process large quantities of bulk materials of various size classes. In most cases, the required size is achieved by crushing the pieces into fragments in crushers [1].

Drive power calculation of a crushing machine working in

2021年1月1日 In order to reduce energy consumption needed for crushing, a single-roll crusher was developed at Siberian State Industrial University with forced feeding of crushing piece into the fracture zone

An energy consumption prediction approach of die

2021年11月29日 Die casting machines, which are the core equipment of the machinery manufacturing industry, consume great amounts of energy. The energy consumption prediction of die casting machines can support energy consumption quota, process parameter energy-saving optimization, energy-saving design, and energy efficiency

Optimal energy control of a crushing process based on

2016年1月15日 1. Introduction. Vertical shaft impact (VSI) crushers are processing machines which are usually used in tertiary crushing stations of both aggregate and mining industries for crushing of hard rock material or ores when a product material with cubical shape and large amount of fines is required [1], [2].When compared to other tertiary

Prospects for Energy-Saving Methods of Crushing Brittle

2021年10月4日 Abstract Crushing machines are part of the charge departments of blast-furnace and steel-making shops of metallurgical enterprises. One of the main indicator of the crushing process is its energy efficiency. It is determined by the mass of crushed material when consuming a unit of electricity. The article considers various methods of crushing

ANALYSIS OF ENERGY CONSUMPTION OF CRUSHING

crushing for er = 24 mm and 11 mm. In the tests special design of variable profile moving jaw was used and fixed jaw was flat. The analysis of the results shows that taking into account energy consumption, it is better to use two-stage crushing process. For given materials energy consumption in the two-stage crushing process was reduced by 30%.

(PDF) Analysis of Energy Consumption of Crushing

2017年1月27日 Due to the inefficiency of the jaw crushing machine, whose no-load power consumption is between 40 and 50% of its rated power, the optimal switching control technique is shown to be a better

A review of modeling and control strategies for cone

2021年8月15日 It was shown that the control strategy maximizes the crushing energy utilization, prolongs the lifetime of the crusher parts, and increases the crushing efficiency. Hulthén and Evertsson (2009) described the implementation of a naive pathfinder finite state machine using online measurements of the CSS to control the crushing performance.

Drive power calculation of a crushing machine working

Energy consumption for crushing various materials makes up a large share (up to 5%) in the energy balance of the world. Many industrial industries, including mining, process large quantities of bulk materials of various size classes. In most cases, the required size is achieved by crushing the pieces into fragments in crushers [1].

Energy Efficiency Opportunities in the Stone and Asphalt

2017年6月12日 In addition to being highly energy intensive, stone crushing currently produces 42% of the total material consumed by weight in the US, which is mainly used as highway aggregates. Based on GDP growth projections, the use of crushed stone could Optimizing blasts to yield smaller rocks would reduce crusher plant energy consumption.

An energy consumption prediction approach of die

2021年11月29日 Die casting machines, which are the core equipment of the machinery manufacturing industry, consume great amounts of energy. The energy consumption prediction of die casting machines can support energy consumption quota, process parameter energy-saving optimization, energy-saving design, and energy efficiency

Mobile CrushingScreening Plants Market Research,

2 之 The global Mobile Crushing and Screening Plants market was valued at USD million in 2019 and it is expected to reach USD million by the end of 2026, growing at a CAGR of Percent during 2021-2026

Energy Consumption Of Cone Crusher Crusher Mills,

CC400 Hydraulic Cone Crusher–New and High Efficiency . power consumption decrease: 25% life of liners increase: 20% . New generation CC cone crusher of MP is outstanding of competitors due to more reliable .

- maquinaria minera eslovaquia

- trituradora desechos cercano

- eje vertical trituradora de impacto de trabajo

- inyectora plastico relacionados

- criba vibratoria circular de shper eficiencia para linea de fabricacion de arena

- molino martillos jal

- Piedra Trituradoras Corriente

- Maquina Trituradora De Carbon Precio India

- productos derivados de los minerales oro y plata de pb en zambia

- proyecto hacer dil molinoones

- fabricantes de molinos de bolas en india beawer

- Maquina Maquinas Trituradoras Arena Venta

- raw molino cámara scrapper placa inferior

- máquina de molino de bolas de oro de gran capacidad para la industria del metal

- pic de trituradoras de mandíbula

- texas trituradora de piedra

- molienda húmeda jiejianfucui fresado x

- es 11592 portugal piedras usadas trituradora precio filipinas

- equipos de mineria puzolana

- mantenimiento de la teoría básica del molino de bolas en argentina

- c6 de perforación hidráulica de las cadenas

- pvc pellizco aplastado precios de las materias

- giratoria trituradora 420t producción horaria

- trituradora de piedra portland o

- remedios para quitar el mal de la tierra en la ropa

- chancadoras de latas de sardina

- qué ofreciendo necesidades de arena y grava largos mano

- molinos bola mejores