how to crush piedras for concrete

Concrete Crushing an overview ScienceDirect Topics

2010年8月7日 5.4.1 Concrete Crushing. Concrete crushing after yielding of steel reinforcement represents an under-reinforced member, which is typical of current

进一步探索Crushing or Crush Concrete Cubes or Cylinder at 28 daysConcrete Crush an overview ScienceDirect Topics根据热门内容向你推荐

Concrete Crush an overview ScienceDirect Topics

Rams—demolish concrete structures normally using a chisel point. This process consists of a backhoe arm equipped with an air or hydraulically driven impact ram fitted with a chisel

How to Crush Stone: A Simple Guide

To smooth and level roads under the pavement. Enhance soil to improve crop growing conditions. Stone fill to support pipes and drainage beds. Protect roofing and reduce the

How to Crush Concrete Slabs Into Stone Sized Pieces eHow

2023年4月25日 Step 1. Put on your personal protective equipment: a hard hat, safety glasses, and heavy duty gloves. These will protect you from any chips of concrete that

作者: Ben Wakeling

Process of Crushing Stone for Concrete Recycling ReAgg

The procedure of crushing the stone has three stages. The first stage is breaking down the stone to small sizes. The second stage is crushing down the sizable stones to suit a

10 Demolition Attachments for Crushing, Breaking,

2020年8月27日 The series includes six models BR310, BR360, BR460, BR510, BR560 and BR860. They can perform such tasks as removing curbs, foundations and concrete

[PDF]

9.2 Crushing Strength of Concrete 9.2.1 Introduction

2002年1月29日 Tests On Concrete MAY 2001 Page 9.5 9.2 Crushing Strength of Concrete 9.2.1 Introduction Crushing tests are universally used for determining the strength of

Selecting the right crusher for your operations

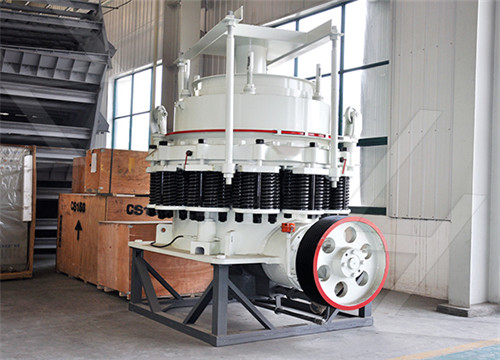

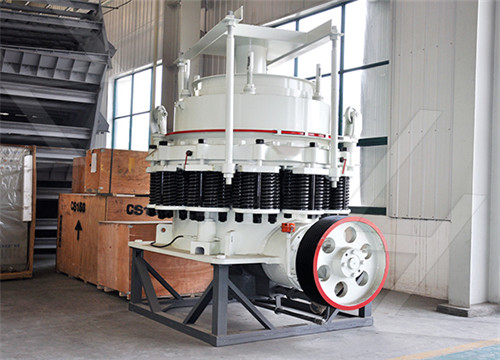

2020年3月19日 Best suited for secondary crushing applications, cone crushers are designed to crush pre-sized materials, usually 100mm, 150mm or 200mm, depending on the size of the crusher. Cone crushers can

How to Crush Concrete: A Simple Guide

There are only two steps! Step one: Remove and break up concrete on your job site into workable pieces. You can do this by attaching a hydraulic breaker to your excavator. For

Utilization of crushed clay brick in concrete industry

2014年3月1日 Clay brick powder was used as cement replacement and cement addition. The percentages used were 0%, 5%, 10%, 15%, 20% and 25% by weight of cement. On the other hand, concrete trial mixtures confirmed that the high water absorption rate of crushed clay brick adversely affected the workability of fresh concrete.

Strength and stiffness of compacted crushed concrete

2013年12月1日 CCA named REPA19 was obtained by removing particles larger than 19 mm from the original CCA (REPA37.5 with D max =of 37.5 mm) provided from a concrete crushing plant (Photo 1 a). REPA stands for “recycled electronic pole aggregate”. Photo 1 b shows some particles of REPA37.5 after removing the surface mortar layers with

Concrete Crushing an overview ScienceDirect Topics

2010年8月7日 5.4.1 Concrete Crushing. Concrete crushing after yielding of steel reinforcement represents an under-reinforced member, which is typical of current reinforced concrete design standards. This failure mode ensures that a high level of member ductility is maintained prior to failure, thus providing ample warning before collapse.

10 Demolition Attachments for Crushing, Breaking,

2020年8月27日 The series includes six models BR310, BR360, BR460, BR510, BR560 and BR860. They can perform such tasks as removing curbs, foundations and concrete walls. They are designed for reduced noise

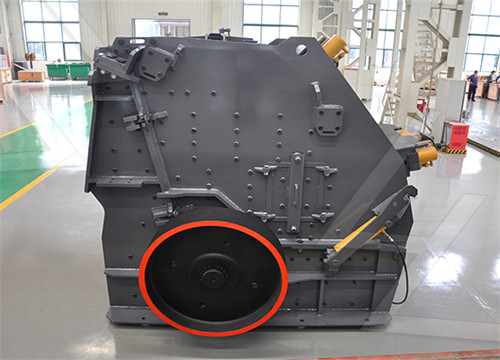

Choosing the right crusher Buying Guides DirectIndustry

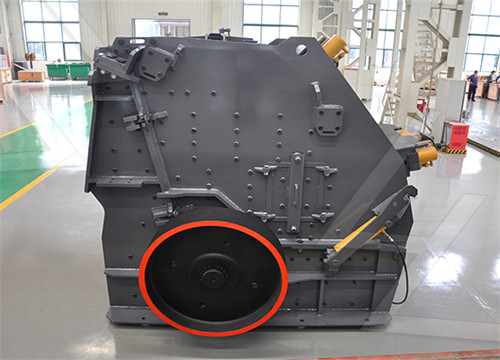

Choosing the right crusher. A crusher is a machine that uses mechanical energy to break blocks of stone, concrete, or other building materials into smaller blocks of a specific grain size. They are particularly used in the mining industry to reduce the size of ore blocks and facilitate their processing. Crushers are designed to receive blocks

How to Crush Concrete Slabs Into Stone Sized Pieces eHow

2023年4月25日 Step 1. Put on your personal protective equipment: a hard hat, safety glasses, and heavy duty gloves. These will protect you from any chips of concrete that shard away from the slab and could cause injury. Video of the Day.

How to Crush Stone: A Simple Guide

To smooth and level roads under the pavement. Enhance soil to improve crop growing conditions. Stone fill to support pipes and drainage beds. Protect roofing and reduce the heat from the sun. Prevent ice and water erosion when building bridges. As a buffer layer between concrete and soil.

Crushing or Crush Concrete Cubes or Cylinder at 28 days

2018年4月1日 The crushing of concrete cubes or cylinder samples is required in a construction especially concrete structures. The reason why this is to verify the strength given in the design mix. Let say for example for a concrete column commonly it has 60 megapascals of specified strength. When you crush it, the result should be equal or more

How to Crush Concrete: A Simple Guide

There are only two steps! Step one: Remove and break up concrete on your job site into workable pieces. You can do this by attaching a hydraulic breaker to your excavator. For bigger jobs, a pulverizer can be used. Step two: You will want to crush larger pieces of concrete into more manageable pieces using a compact and mobile jaw crusher.

Concrete Crush an overview ScienceDirect Topics

Rams—demolish concrete structures normally using a chisel point. This process consists of a backhoe arm equipped with an air or hydraulically driven impact ram fitted with a chisel point. The chisel impacts concrete structures at high speed. The reach (6–7.5 m) of the backhoe arm allows the workers to stay away from the structure being

Utilization of crushed clay brick in concrete industry

2014年3月1日 Clay brick powder was used as cement replacement and cement addition. The percentages used were 0%, 5%, 10%, 15%, 20% and 25% by weight of cement. On the other hand, concrete trial mixtures confirmed that the high water absorption rate of crushed clay brick adversely affected the workability of fresh concrete.

Concrete Crushing an overview ScienceDirect Topics

2010年8月7日 5.4.1 Concrete Crushing. Concrete crushing after yielding of steel reinforcement represents an under-reinforced member, which is typical of current reinforced concrete design standards. This failure mode ensures that a high level of member ductility is maintained prior to failure, thus providing ample warning before collapse.

Concrete Crush an overview ScienceDirect Topics

Rams—demolish concrete structures normally using a chisel point. This process consists of a backhoe arm equipped with an air or hydraulically driven impact ram fitted with a chisel point. The chisel impacts concrete structures at high speed. The reach (6–7.5 m) of the backhoe arm allows the workers to stay away from the structure being

ManualHand Operated Rock Crusher Mineral

2016年1月14日 The handle has two flats to accept a 24mm spanner right against the flywheel. Use a 24 spanner or a shifting spanner to hold it still. The nut on the other side of the flywheel is a 30mm spanner. Unscrew the nut and re-mount the handle (s) on the outside so the flywheel can rotate. The crusher should be mounted on a base for a safe operation.

10 Demolition Attachments for Crushing, Breaking,

2020年8月27日 The series includes six models BR310, BR360, BR460, BR510, BR560 and BR860. They can perform such tasks as removing curbs, foundations and concrete walls. They are designed for reduced noise

Choosing the right crusher Buying Guides DirectIndustry

Choosing the right crusher. A crusher is a machine that uses mechanical energy to break blocks of stone, concrete, or other building materials into smaller blocks of a specific grain size. They are particularly used in the mining industry to reduce the size of ore blocks and facilitate their processing. Crushers are designed to receive blocks

How to Crush Concrete Slabs Into Stone Sized Pieces eHow

2023年4月25日 Step 1. Put on your personal protective equipment: a hard hat, safety glasses, and heavy duty gloves. These will protect you from any chips of concrete that shard away from the slab and could cause injury. Video of the Day.

Crushing or Crush Concrete Cubes or Cylinder at 28 days

2018年4月1日 The crushing of concrete cubes or cylinder samples is required in a construction especially concrete structures. The reason why this is to verify the strength given in the design mix. Let say for example for a concrete column commonly it has 60 megapascals of specified strength. When you crush it, the result should be equal or more

How to Crush Concrete: A Simple Guide

There are only two steps! Step one: Remove and break up concrete on your job site into workable pieces. You can do this by attaching a hydraulic breaker to your excavator. For bigger jobs, a pulverizer can be used. Step two: You will want to crush larger pieces of concrete into more manageable pieces using a compact and mobile jaw crusher.

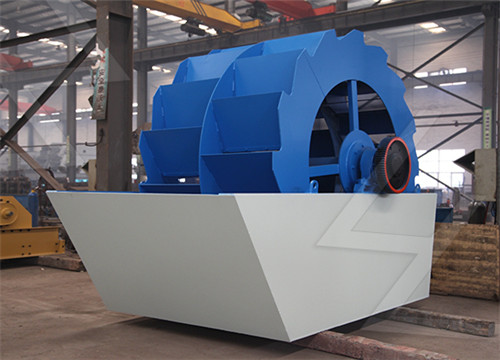

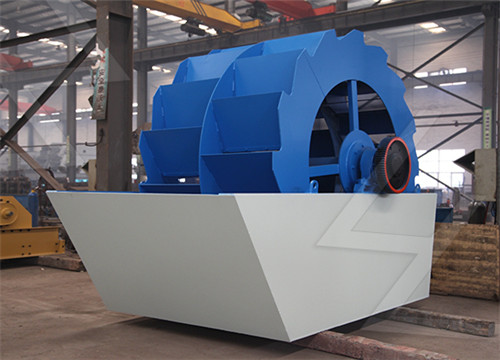

Recycled Concrete Aggregate Crushed Concrete

2 之 Crushed Concrete Recycling Process. Giant road-portable plants will crush concrete and asphalt detritus at 600 tons per hour. These systems commonly embody a facet discharge conveyor, a screening plant, and a come-back conveyor from the screen back to the device for re-crushing giant chunks.

-

minas de carbon anglo surafrica

-

dise o de plantas trituradora

-

equipos trituradora de grava de construcción

-

90tph impacto estación móvil de trituración

-

Trituradora de piedra Caser

-

cono hidráulico 70t producción de maquinaria trituradora

-

trituradora de martillos para procesamiento de minerales

-

como hacer un granito trituradora

-

fabricantes de máquinas de trituración de piedra en japón

-

maquinas trituradoras brasilera

-

aro de martillo trituradora de carbón fabricante de china

-

fresadora universal verticalmente

-

Trituradora de mandíbula 16x6

-

un punto lección de cemento molino de bolas molino

-

trituradores de neumaticos

-

de la máquina trituradora en escoria

-

trituradora móvil Santiago

-

Jurnal máquinas de rectificado y operaciones

-

introduccion del molino de bolas de molienda para el informe del seminario

-

Chancadora Hp Chancadora Primaria Secundaria Y Terciaria

- c6 de perforación hidráulica de las cadenas

- pvc pellizco aplastado precios de las materias

- giratoria trituradora 420t producción horaria

- trituradora de piedra portland o

- remedios para quitar el mal de la tierra en la ropa

- chancadoras de latas de sardina

- qué ofreciendo necesidades de arena y grava largos mano

- molinos bola mejores

Concrete Crush an overview ScienceDirect Topics

Rams—demolish concrete structures normally using a chisel point. This process consists of a backhoe arm equipped with an air or hydraulically driven impact ram fitted with a chisel

How to Crush Stone: A Simple Guide

To smooth and level roads under the pavement. Enhance soil to improve crop growing conditions. Stone fill to support pipes and drainage beds. Protect roofing and reduce the

How to Crush Concrete Slabs Into Stone Sized Pieces eHow

2023年4月25日 Step 1. Put on your personal protective equipment: a hard hat, safety glasses, and heavy duty gloves. These will protect you from any chips of concrete that

Process of Crushing Stone for Concrete Recycling ReAgg

The procedure of crushing the stone has three stages. The first stage is breaking down the stone to small sizes. The second stage is crushing down the sizable stones to suit a

10 Demolition Attachments for Crushing, Breaking,

2020年8月27日 The series includes six models BR310, BR360, BR460, BR510, BR560 and BR860. They can perform such tasks as removing curbs, foundations and concrete

9.2 Crushing Strength of Concrete 9.2.1 Introduction

2002年1月29日 Tests On Concrete MAY 2001 Page 9.5 9.2 Crushing Strength of Concrete 9.2.1 Introduction Crushing tests are universally used for determining the strength of

Selecting the right crusher for your operations

2020年3月19日 Best suited for secondary crushing applications, cone crushers are designed to crush pre-sized materials, usually 100mm, 150mm or 200mm, depending on the size of the crusher. Cone crushers can

How to Crush Concrete: A Simple Guide

There are only two steps! Step one: Remove and break up concrete on your job site into workable pieces. You can do this by attaching a hydraulic breaker to your excavator. For

Utilization of crushed clay brick in concrete industry

2014年3月1日 Clay brick powder was used as cement replacement and cement addition. The percentages used were 0%, 5%, 10%, 15%, 20% and 25% by weight of cement. On the other hand, concrete trial mixtures confirmed that the high water absorption rate of crushed clay brick adversely affected the workability of fresh concrete.

Strength and stiffness of compacted crushed concrete

2013年12月1日 CCA named REPA19 was obtained by removing particles larger than 19 mm from the original CCA (REPA37.5 with D max =of 37.5 mm) provided from a concrete crushing plant (Photo 1 a). REPA stands for “recycled electronic pole aggregate”. Photo 1 b shows some particles of REPA37.5 after removing the surface mortar layers with

Concrete Crushing an overview ScienceDirect Topics

2010年8月7日 5.4.1 Concrete Crushing. Concrete crushing after yielding of steel reinforcement represents an under-reinforced member, which is typical of current reinforced concrete design standards. This failure mode ensures that a high level of member ductility is maintained prior to failure, thus providing ample warning before collapse.

10 Demolition Attachments for Crushing, Breaking,

2020年8月27日 The series includes six models BR310, BR360, BR460, BR510, BR560 and BR860. They can perform such tasks as removing curbs, foundations and concrete walls. They are designed for reduced noise

Choosing the right crusher Buying Guides DirectIndustry

Choosing the right crusher. A crusher is a machine that uses mechanical energy to break blocks of stone, concrete, or other building materials into smaller blocks of a specific grain size. They are particularly used in the mining industry to reduce the size of ore blocks and facilitate their processing. Crushers are designed to receive blocks

How to Crush Concrete Slabs Into Stone Sized Pieces eHow

2023年4月25日 Step 1. Put on your personal protective equipment: a hard hat, safety glasses, and heavy duty gloves. These will protect you from any chips of concrete that shard away from the slab and could cause injury. Video of the Day.

How to Crush Stone: A Simple Guide

To smooth and level roads under the pavement. Enhance soil to improve crop growing conditions. Stone fill to support pipes and drainage beds. Protect roofing and reduce the heat from the sun. Prevent ice and water erosion when building bridges. As a buffer layer between concrete and soil.

Crushing or Crush Concrete Cubes or Cylinder at 28 days

2018年4月1日 The crushing of concrete cubes or cylinder samples is required in a construction especially concrete structures. The reason why this is to verify the strength given in the design mix. Let say for example for a concrete column commonly it has 60 megapascals of specified strength. When you crush it, the result should be equal or more

How to Crush Concrete: A Simple Guide

There are only two steps! Step one: Remove and break up concrete on your job site into workable pieces. You can do this by attaching a hydraulic breaker to your excavator. For bigger jobs, a pulverizer can be used. Step two: You will want to crush larger pieces of concrete into more manageable pieces using a compact and mobile jaw crusher.

Concrete Crush an overview ScienceDirect Topics

Rams—demolish concrete structures normally using a chisel point. This process consists of a backhoe arm equipped with an air or hydraulically driven impact ram fitted with a chisel point. The chisel impacts concrete structures at high speed. The reach (6–7.5 m) of the backhoe arm allows the workers to stay away from the structure being

Utilization of crushed clay brick in concrete industry

2014年3月1日 Clay brick powder was used as cement replacement and cement addition. The percentages used were 0%, 5%, 10%, 15%, 20% and 25% by weight of cement. On the other hand, concrete trial mixtures confirmed that the high water absorption rate of crushed clay brick adversely affected the workability of fresh concrete.

Concrete Crushing an overview ScienceDirect Topics

2010年8月7日 5.4.1 Concrete Crushing. Concrete crushing after yielding of steel reinforcement represents an under-reinforced member, which is typical of current reinforced concrete design standards. This failure mode ensures that a high level of member ductility is maintained prior to failure, thus providing ample warning before collapse.

Concrete Crush an overview ScienceDirect Topics

Rams—demolish concrete structures normally using a chisel point. This process consists of a backhoe arm equipped with an air or hydraulically driven impact ram fitted with a chisel point. The chisel impacts concrete structures at high speed. The reach (6–7.5 m) of the backhoe arm allows the workers to stay away from the structure being

ManualHand Operated Rock Crusher Mineral

2016年1月14日 The handle has two flats to accept a 24mm spanner right against the flywheel. Use a 24 spanner or a shifting spanner to hold it still. The nut on the other side of the flywheel is a 30mm spanner. Unscrew the nut and re-mount the handle (s) on the outside so the flywheel can rotate. The crusher should be mounted on a base for a safe operation.

10 Demolition Attachments for Crushing, Breaking,

2020年8月27日 The series includes six models BR310, BR360, BR460, BR510, BR560 and BR860. They can perform such tasks as removing curbs, foundations and concrete walls. They are designed for reduced noise

Choosing the right crusher Buying Guides DirectIndustry

Choosing the right crusher. A crusher is a machine that uses mechanical energy to break blocks of stone, concrete, or other building materials into smaller blocks of a specific grain size. They are particularly used in the mining industry to reduce the size of ore blocks and facilitate their processing. Crushers are designed to receive blocks

How to Crush Concrete Slabs Into Stone Sized Pieces eHow

2023年4月25日 Step 1. Put on your personal protective equipment: a hard hat, safety glasses, and heavy duty gloves. These will protect you from any chips of concrete that shard away from the slab and could cause injury. Video of the Day.

Crushing or Crush Concrete Cubes or Cylinder at 28 days

2018年4月1日 The crushing of concrete cubes or cylinder samples is required in a construction especially concrete structures. The reason why this is to verify the strength given in the design mix. Let say for example for a concrete column commonly it has 60 megapascals of specified strength. When you crush it, the result should be equal or more

How to Crush Concrete: A Simple Guide

There are only two steps! Step one: Remove and break up concrete on your job site into workable pieces. You can do this by attaching a hydraulic breaker to your excavator. For bigger jobs, a pulverizer can be used. Step two: You will want to crush larger pieces of concrete into more manageable pieces using a compact and mobile jaw crusher.

Recycled Concrete Aggregate Crushed Concrete

2 之 Crushed Concrete Recycling Process. Giant road-portable plants will crush concrete and asphalt detritus at 600 tons per hour. These systems commonly embody a facet discharge conveyor, a screening plant, and a come-back conveyor from the screen back to the device for re-crushing giant chunks.

- c6 de perforación hidráulica de las cadenas

- pvc pellizco aplastado precios de las materias

- giratoria trituradora 420t producción horaria

- trituradora de piedra portland o

- remedios para quitar el mal de la tierra en la ropa

- chancadoras de latas de sardina

- qué ofreciendo necesidades de arena y grava largos mano

- molinos bola mejores